Flow testing is the process of checking and adjusting the output of a hydraulic pump under load, to ensure the correct volume of oil is being supplied at the various pressures the system operates under.

Why is this necessary?

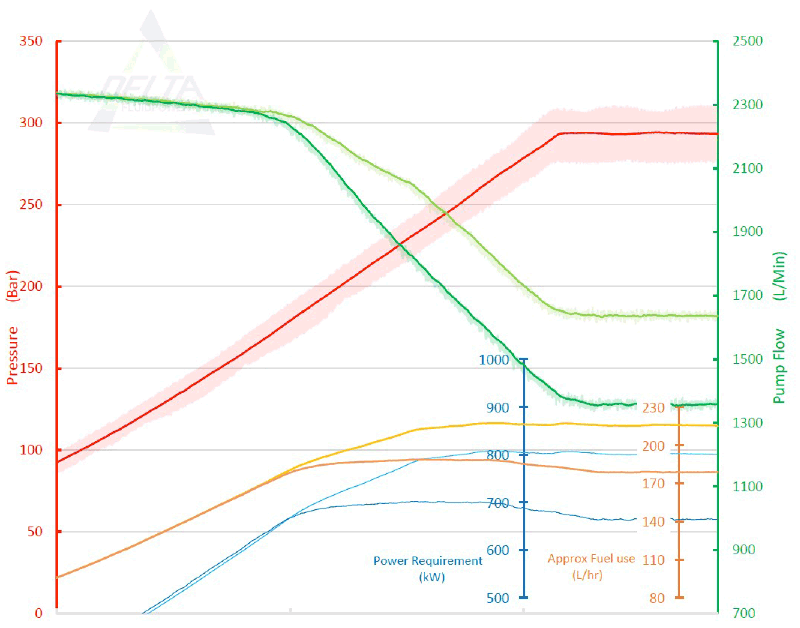

Diesel engine driven systems have a maximum usable horsepower output available, the amount of horsepower a hydraulic pump consumes is a direct calculation of the flow multiplied by the pressure in the system.

(GPM x PSI)/1714 = HP

or

(L/min x Bar)/600 = kW

- If the flow rate of the pump is too high at a given pressure then the engine is unable to maintain its desired output, causing an increase in engine load beyond OEM recommendations, increased fuel usage, if pump load becomes too high it can cause the engine to “bog down”, “hunt” or even stall completely.

- If the flow rate is too low, the machine is unable to achieve performance requirements.

In addition to increased engine load and excess fuel consumption other effects of incorrectly adjusted hydraulic pump controls can be over heating of the hydraulics system, which in turn:

- Increases wear on system components

- Reduces hydraulic oil life span and deteriorates hydraulic oil anti-wear properties

- Increased “varnish potential” of the hydraulic oil