Delta Fluidpower is a privately-owned company, located in Central Queensland. We design and build control systems and hydraulic solutions for the mining, agriculture and construction industries.

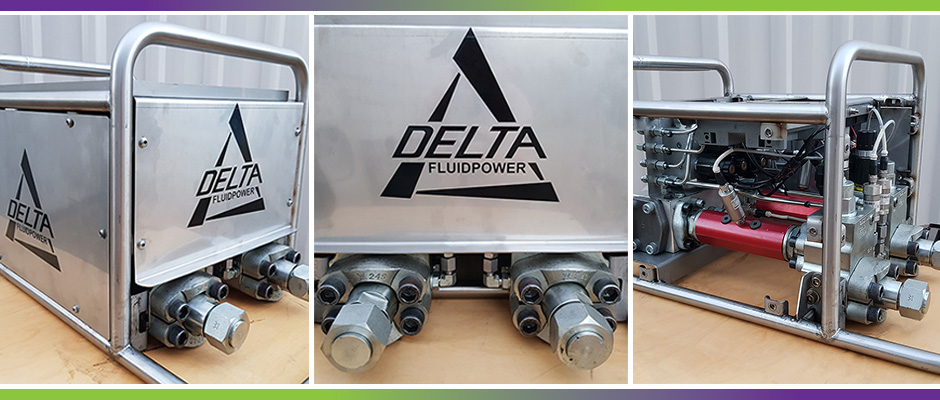

As our first product to market, we have developed our Dual Input Flow Meter Assembly (D.I.F.M.A.). Used as part of a good maintenance plan, you will be able to reduce fuel costs, increase availability and pump reliability, while providing a safe test environment for your maintainers.

This video was made for the Queensland Mining Industry Safety Awards, 2018. It shows our early prototype, before the addition of integrated electronic controls, further development and testing.

The current DIFMA model has had an extensive Design Risk Assessment and Failure Modes Effects and Criticality Analysis (FMECA) carried out by an independent functional safety engineer.

The Dual Input Flow Meter Assembly system has been audited to ensure compliance with:

– MDG41 Fluid Power Safety Systems at Mines (Mining Design Guidelines NSW)

– Draft Version, Recognised Standard – Fluid Power Safety in Coal Mines (Qld).

More information

Want to know more? Shoot us a message…

Testimonial

Delta Fluidpower have developed a world class engineering solution that eliminates the risk of high pressure fluid injection to maintainers whilst undertaking hydraulic flow testing. The innovation is simple to operate and provides greater understanding of hydraulic system performance than methods previously used through the ability to undertake flow data trend analysis.

This analysis has resulted in a reduction in maintenance costs through the early detection of pump failure, allowing timely replacement or repair during scheduled maintenance windows, as opposed to lost time during replacement upon failure.

Our maintainers prefer the ease of application to previous methods and the obvious benefit of eliminating the safety risk whilst undertaking hydraulic flow testing of our fleet.

Jon Noble

Health Safety and Training Manager

Clermont Open Cut Mine